Technical Information

Wheel and Tyre Technical Information

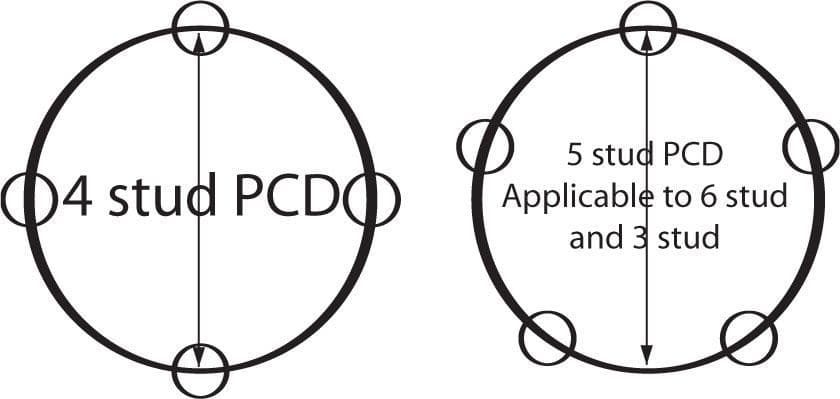

PCD - Pitch Circle Diameter

In general the number of holes for most vehicles in today’s market ranges from 3 to 8, depending on make and model. The PCD of a wheel is an imaginary circle that passes through the centre of each mounting hole. It is essential that when fitting aftermarket wheels the new wheel is of the correct PCD for the vehicle. For 4 stud wheels this can simply be calculated by measuring from the middle of the top left stud hole to the centre of the bottom right. For 3, 5, 6 and 8 hole applications an imaginary circle must be drawn through the centre of each stud hole to determine the correct PCD as shown below.

Centre Location

Although several manufacturers may use the same PCD it is often the case that they may use a differing central spigot location diameter. In this case a nylon, plastic or metal 'spigot ring' will be supplied carrying the correct inside diameter. It is vital that it is verified that the ring supplied not only corresponds to the spigot diameter of the vehicle but also with the location hole on the rear of the wheels centre hole otherwise vibration, and in extreme cases loss of the wheel itself, will occur.

Minimum thread engagement

It is widely accepted that there must be adequate thread engagement when fitting aftermarket wheels. As a general rule, for threads with a 1.5mm pitch this is 6 full turns and with fitments using a 1.25mm pitch this is 9 full turns.

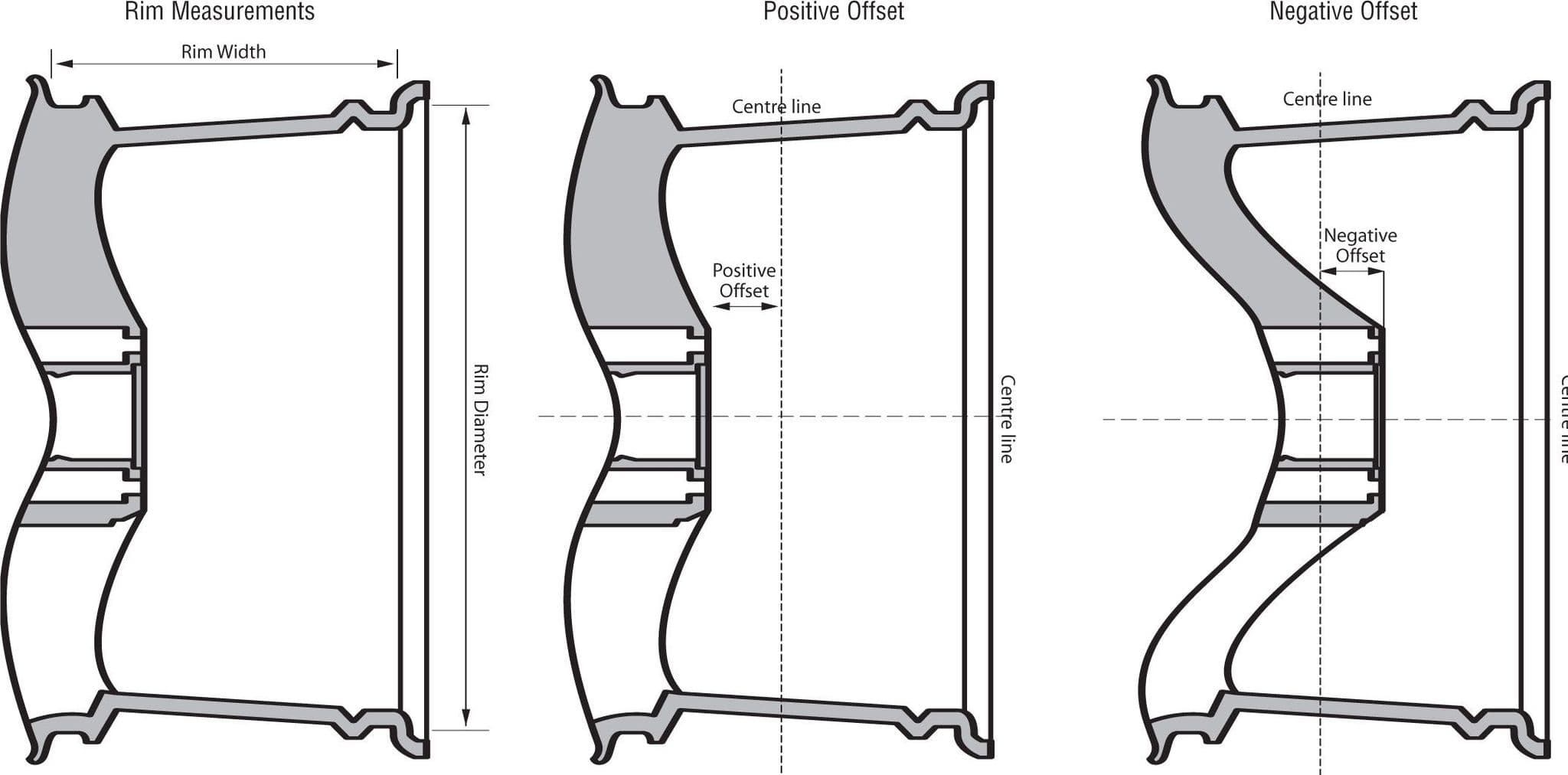

Offset - The offset of a wheel is the measurement from a wheels imaginary centre line to the mounting face. For most modern vehicles the offset will be positive which means that the mounting face is forward of the centre line bringing the wheel further under the bodywork of the car. Older cars and some 4x4 vehicles will have a negative offset which pushes the wheel outwards from the cars bodywork. Aftermarket wheels may have less of an offset than the vehicles standard wheel and this is to accommodate the fact that the aftermarket wheel is invariably wider than the vehicles standard wheels but it must be stressed that too greater an offset reduction will greatly effect the cars stability and road holding and will cause accelerated wear to drive train and suspension components.

Tyre Information

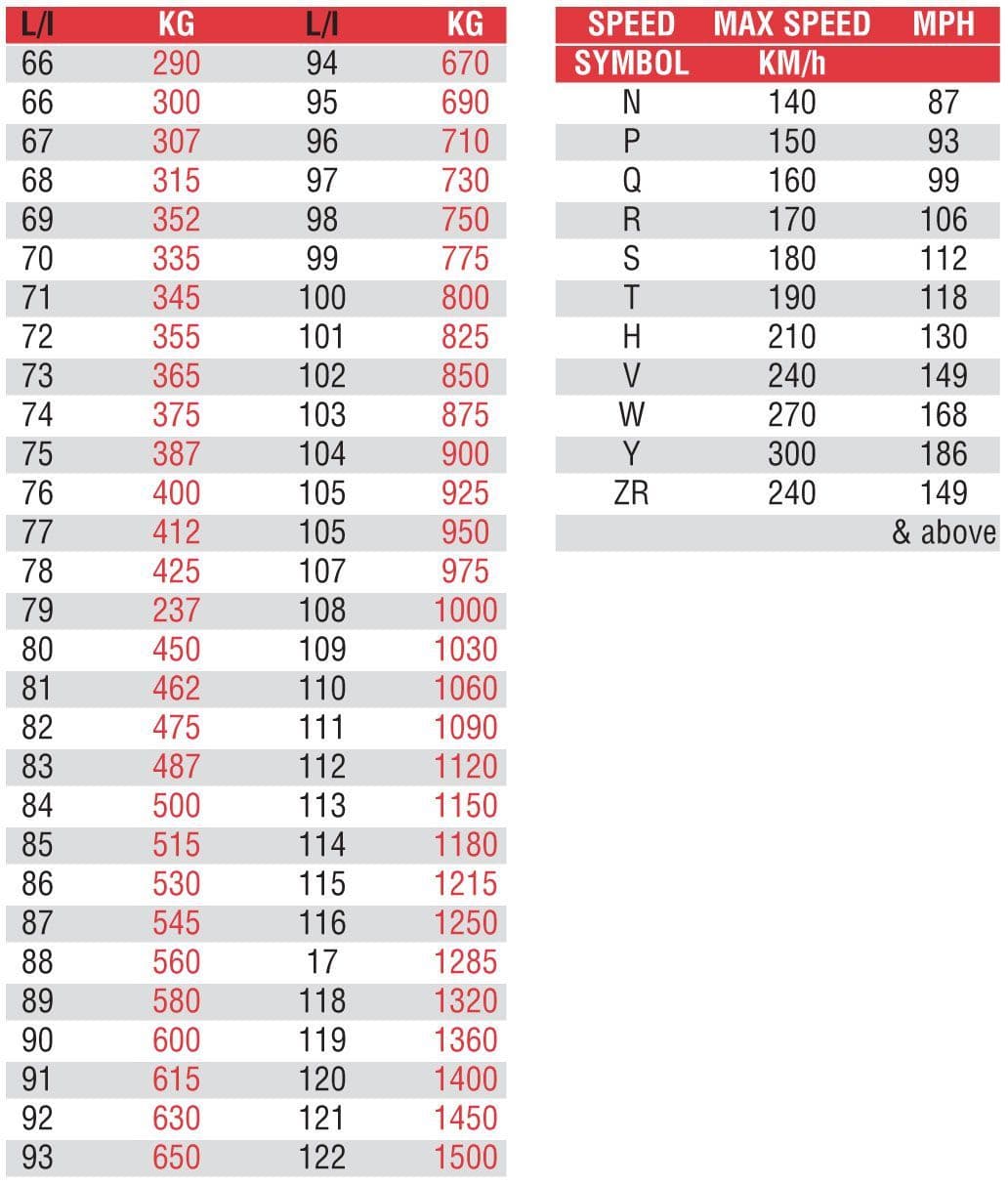

Load Index

The load-index figure imprinted on the sidewall of the tyre denotes the maximum load capacity of a tyre when driven at maximum speed. A chart of load indexes and maximum weights is listed below, based on tyre inflation pressures of 35 psi.

Speed Index

All tyres carry a speed symbol in the form of a letter indicating the maximum speed for which the tyre is intended to be used. The chart below shows which speed goes with each letter.

Tread Depth

The current tread depth legislation require car tyres must have a minimum of 1.6mm of tread in a continuous band throughout the central 3/4 of the tread width and over the whole circumference of the tyre.